The innovative duo combines forming and tapping in a single operation, boosting efficiency in sheet metal part production. With a versatile cutting head, it can handle different materials and thicknesses without the need for head changes. This integration seamlessly incorporates laser, punching, and forming tools for comprehensive part processing.

The highly productive punch laser processing cell

Introducing the latest generation TruMatic 5000 with SheetMaster, transforms the material flow in your punch laser production. This advanced system seamlessly handles fast loading, unloading, palletising, and sorting tasks. Boasting 6 kW of laser power, the TruMatic 5000 sets unprecedented productivity benchmarks while maintaining remarkable energy efficiency. Equipped with nozzle changers, pre-separation of sheets parallel to production, an integrated axis for enhanced flexibility, and a range of individually controllable suction cups, it empowers autonomous and efficient production processes.

Maximum productivity

- The powerful 6 kW laser on the TruMatic 5000 makes your punch laser processing highly productive.

Fully automated

- The automated punch laser system is ideal for multi-shift operation.

Scratch-free processing

- The descending die enables scratch-free punching and forming processes.

Autonomous production

- The ToolMaster changes tools fully automatically in the machine – for maximum safety in processes.

Large variety of materials

- In addition to standard materials, the laser cuts a wide range of non-ferrous metals productively and reliably.

Efficient and energy-saving

- The machine’s solid-state lasers and delta drive score points for efficiency and energy conservation.

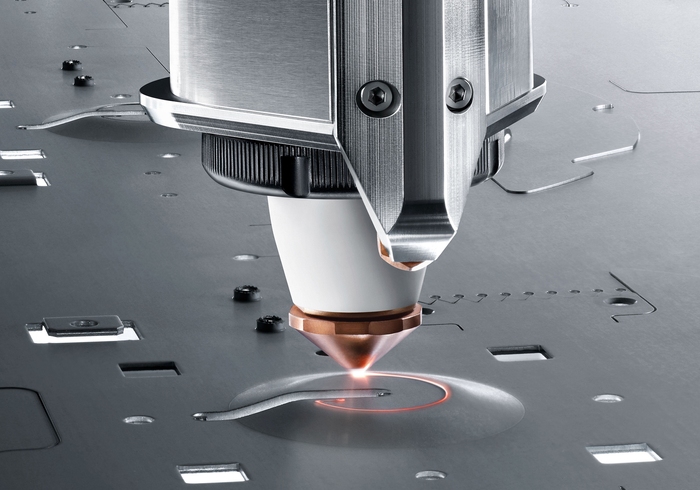

One cutting head for everything

With the TruMatic 5000, you can process all types of materials and thicknesses with the same cutting head due to the beam guidance. There is no need to change the head, meaning that non-productive times are reduced.

Complete processing of the part

The perfect synergy between laser, punching and forming tools enables the complete processing of your parts. This usually eliminates downstream operations, such as deburring.

Easy tool handling

The ToolMaster is loaded parallel to production – prepared tools are brought into the tool changer without interrupting production and tools are removed for regrinding. Whether for a nozzle change or tool change: Due to its varied automation components, the TruMatic 5000 operates reliably around the clock.

Are you ready to unlock maximum productivity, automation, scratch-free processing, autonomous production, and unmatched material versatility in your sheet metal fabrication?

Reach out to our TRUMPF experts today to explore how the TruMatic 5000 with SheetMaster can transform your operations.