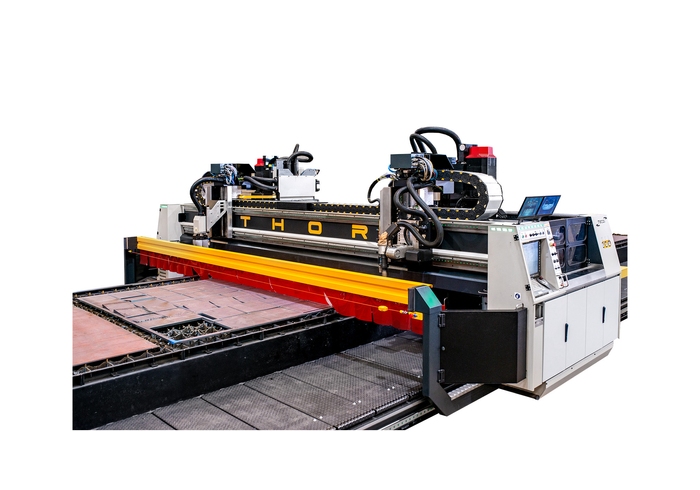

THOR is the most versatile plate processing station on the market, combining high-performance thermal and mechanical cutting. It allows manufacturing parts with multiple operations such as milling, drilling, tapping, countersinking, marking, as well as mechanised or thermal-cut edge finishing. Its design, maximum strength and ultra-reinforced guidance have been developed for heavy-duty applications and maximum productivity. It handles complex shapes, large sizes and high-strength materials making it indispensable for the steel industry, particularly in submarine and defence shipbuilding. Due to all the available options, it is easy to adapt to every customer according to their production needs.

THOR was created in response to some of the high requirements and standards of TECOI’s customers like Murray Steel Buildings, who has extensive experience in supplying steel to the shipbuilding and marine repairs industries, collaborating with commercial yards and Ministry of Defence contractors. The most interesting aspect of THOR is its ability to perform both thermal cutting and machining operations on thick materials. Previously, separate machines were required for these tasks, which was time-consuming and inefficient. THOR solves this problem by combining these capabilities into a single, versatile machine. Its heavy-duty processing power allows it to handle large thicknesses of material with ease by integrating these functionalities.

About Murray Steel Building: Murray Steel Buildings, situated in Dunfermline, Scotland, specialises in the design, supply, and installation of steel structures. Their services also cater to the specific requirements of both the shipbuilding and marine repairs industry throughout the United Kingdom. Established in 2019, the company offers top-quality steel structures for industrial, commercial, agricultural, and residential applications. Despite its small team of 2-10 employees, Murray Steel Buildings has gained a reputation for exceptional service and custom designs tailored to meet clients’ unique requirements. Since adding the TECOI technology to their capabilities, Murray Steel established itself as a trusted supplier of steel to manufacturers in the defence sector, supporting Ministry of Defence contractors and companies involved in exporting products. Murray Steel Buildings website

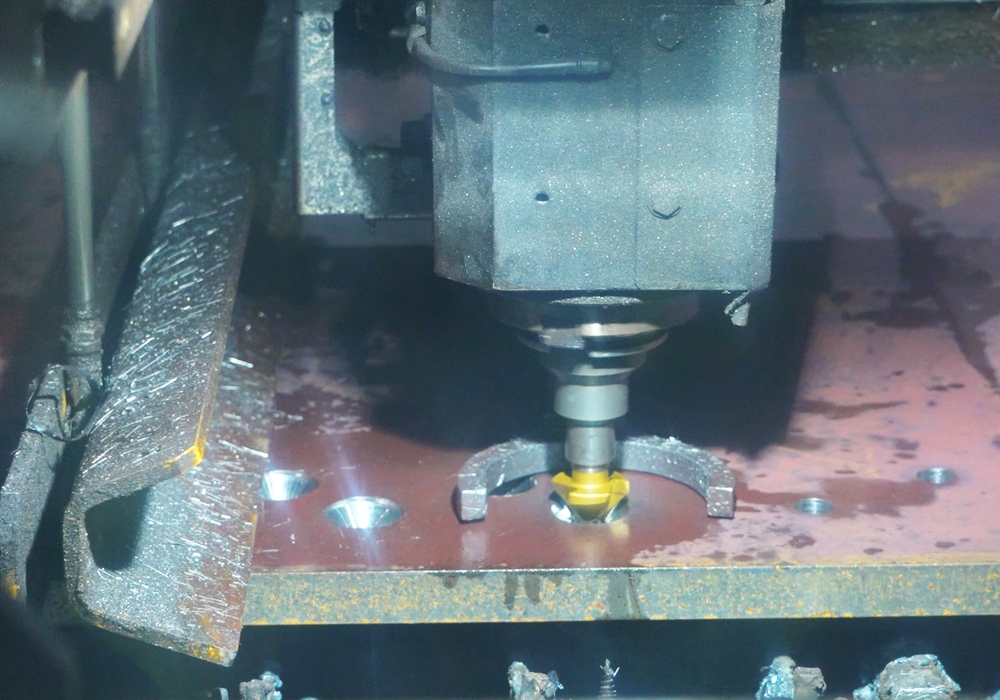

A system combining thermal cutting and machining with innovative DRILTEC heads

Another relevant feature of the DRILTEC is that it automatically recognises the machining tool that has to be used. A tool magazine – one per DRILTEC head – is placed on the side of the THOR, which, based on the nesting, identifies the ideal tool for each application and sends the DRILTEC head to pick it and leave the old one.

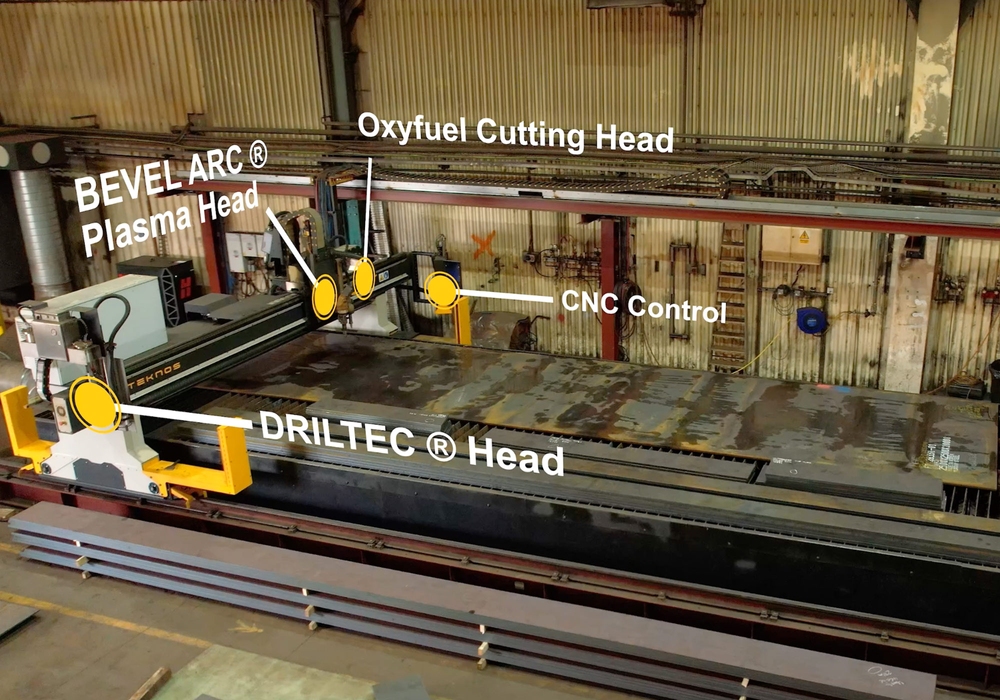

Versatile THOR plasma torch: enabling high-quality cutting, marking, and bevelling

Apart from the DRILTEC heads, THOR plasma torch is one of its most crucial components, as it is in charge of channelling the plasma arc for high-quality cutting. These machines can equip one or two plasma cutting heads on the same gantry, also able to perform high-definition plasma marking and 5-axis bevelling as well, thanks to TECOI exclusive technology BEVEL ARC. This bevelling system confers the plasma heads an extraordinary tilting angle – from +50º to -50º in 1.2 seconds – making it possible to produce high-quality parts with complex geometries in reduced times, avoiding unnecessary loops and providing better use of the plate. Taking its versatility even further, THOR can incorporate up to 12 oxyfuel cutting torches in the back or at the forefront of its gantry to process large thicknesses.

Optimising precision and efficiency in shipbuilding, submarine construction, and defence manufacturing

The THOR DRILTEC head combines precision, efficiency, versatility, reliability, and safety, making it an invaluable tool for optimising drilling operations essential to shipbuilding, submarine construction, and defence manufacturing.

- Extremely precise drilling capabilities that meet stringent tolerances required

- Significantly increases productivity and reduces construction timelines

- Versatile and can drill through various materials like steel, aluminium, composites

- Robust and reliable design minimises equipment downtime

- Incorporates advanced safety features to protect workers from drilling hazards

- Allows these industries to streamline processes, enhance quality, and maintain a competitive edge

- Innovative drilling systems designed to meet the demanding requirements of these sectors

Maximising machining capabilities solution for the shipbuilding industry

Our TECOI solution offerings enhance efficiency and productivity in the defence and shipbuilding industry. From precision plasma cutting to machining operations, we provide tools to optimise metal fabrication processes, meeting industry demands with high-quality standards.

Contact our TECOI technology experts today and discover how our solutions can transform your operations, just as they have for industry leaders like Murray Steel.