CEO Update: A Message from George Yammouni

As economic headwinds persist, Headland continues to innovate, grow, and look confidently toward 2025.

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

Timesavers deburring and linishing machines provide high-quality metal finishing. They are suited to a variety of metal types including but not limited to copper, aluminum, stainless steel and mild steel.

Eliminate surface roughness. Oxide removal. Rounding edges. Sheet metal deburring tool. Metal finishing.

The Timesavers 10 Series deburring machine is a versatile and capable starter linishing machine. A cost-saving alternative to manual deburring, rounding edges and finishing your sheet metal.

The Timesavers 12 Series is a dry working deburring machine that can be equipped with an abrasive belt, disc or both. Deburr a huge variety of metals including copper, aluminum, stainless steel and mild steel.

The Timesavers 22 Series Deburring and Linishing Machine is perfect for dry finishing and metal deburring. A highly versatile machine it comes in three widths: 900 mm, 1050 mm, 1280 mm.

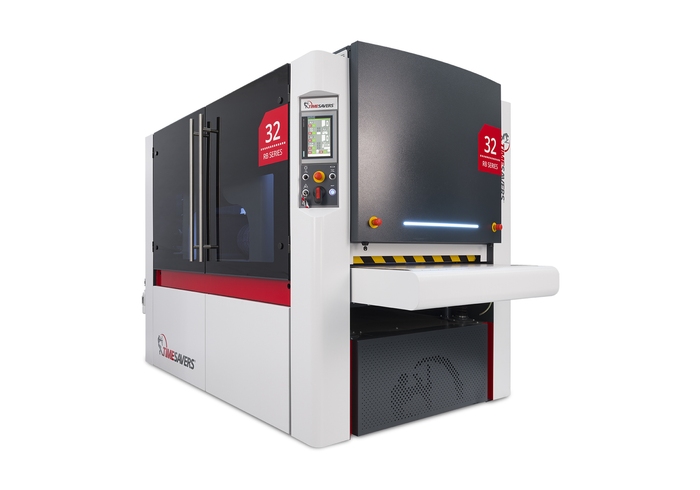

The Timesavers 32 series deburring machine is suitable for a wide array of metal parts. This linishing machine is compact and perfect for deburring, edge rounding, and finishing metal parts.

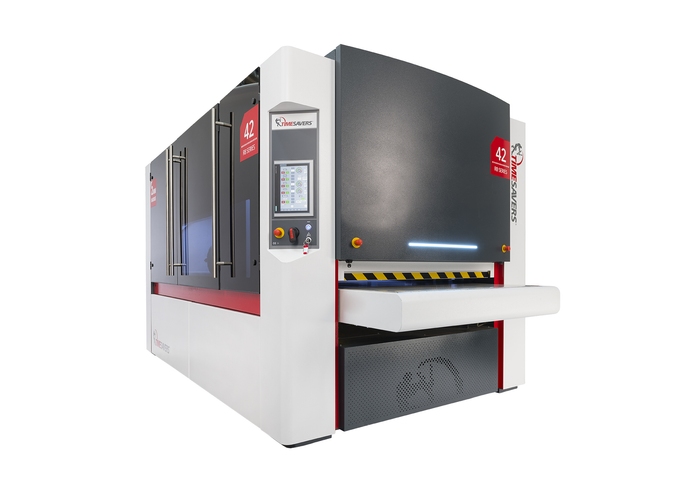

The Timesavers 42 series deburring machine is a superior solution for perfect finishing of metal cut parts. The 42 RB series ensures a high-end and smooth finish. Available in 1350 mm and 1600 mm width.

The process of deburring sheet metal involves removing sharp edges and irregularities from metal products. Burrs are small bits of metal that are adhered to the sheet metal’s surface, primarily in the vicinity of the cut edges. These are brought on by machining processes like plasma, water jet, laser, and punched cutting.

We can help you to find the perfect deburring machine or linishing machine for your manufacturing needs. Please fill out the form and one of our deburring specialists will get in touch with you soon.

In addition to supplying you industry-leading manufacturing equipment, we provide machine servicing, software support and smart manufacturing consulting for all our brands.