Sustainability and eco-conscious design are becoming increasingly important considerations in product development. One area where sustainability can be improved is plastic injection moulding, a common manufacturing process used to produce plastic parts and products at scale. An innovative solution is to use natural materials like spent coffee grounds as a filler in injection moulded plastic parts.

Coffee grounds are an abundant waste material produced during the coffee-making process. Usually discarded in landfills, repurposing used grounds for injection moulding helps give this waste a second life and diverts it from landfills. The grounds can be dried, processed and mixed with plastic resin to create a composite material.

This composite can then be injection moulded into products like cup coasters and serveware. The addition of coffee grounds reduces the amount of plastic required per part, lowering raw material usage. The grounds also impart a natural brown colour and textured appearance, ideal for earthy and stylish designs. As a further sustainability benefit, the use of biowaste-like grounds can result in products that are compostable at end-of-life.

How Gebaplast uses coffee grounds to produce new stylish cup coasters

About Gebaplast: Gebaplast is a small, family-owned injection moulding company. They focus on special products, such as coffee injection, special designs and engineering (www.drumclip.nl), or innovative products in professional gardening and Datacenter applications (www.dataplast.nl). Their service varies from injection moulding high-quality materials to making thin-wall products. This diversity in possibilities makes Gebaplast an all-round injection mould company. www.gebaplast.nl

For more sustainable coffee enjoyment

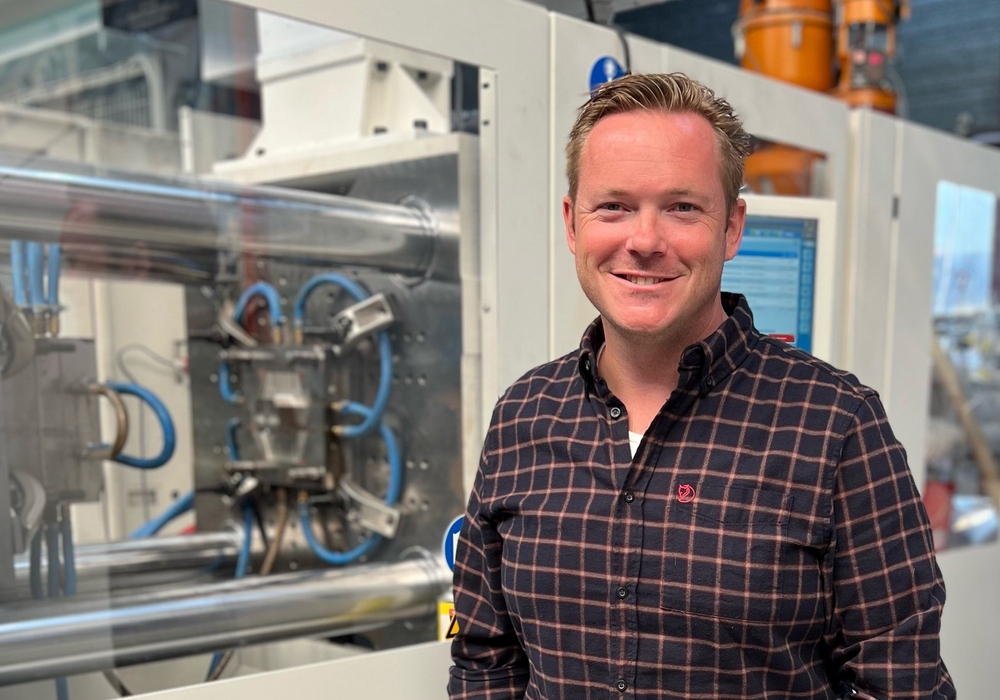

Reusing something good makes sense — and that is also how they see it at Gebaplast BV in Oud-Beijerland, Netherlands. The family-owned company produces coffee-cup coasters made of biopolymers based on ground coffee. For production, they use a CX 130-750 injection moulding machine from KraussMaffei. An interview with company owner Wouter Geldhof.

Coasters based on ground coffee beans; are certainly a rather unusual project for an injection moulding company. How did this start?

Owner Wouter Geldhof answers:

“The request came from a customer. That customer, in turn, had been approached by a major provider of coffee and fully automatic coffee machines to produce stylish coasters for cups for its collection of accessories. What is extraordinary about this is that used coffee bean grounds are to serve as the material. This is an excellent project, which we at Gebaplast as an agile family-owned company were glad to accept. We like thinking outside the box and developing new solutions for and with our customers.”

What type of material is biopolymer and what is it exactly?

Wouter Geldhof replies:

“We fully process a biopolymer, and it is called a bio-PE. The percentage of used coffee bean grounds is 25 percent. A nice side effect is that the coffee aroma is not lost, so the coasters still smell like coffee. The coasters are designed for a long service life and are dishwasher-safe. But if a product ever needs to be disposed of, they are 100 percent recyclable.”

Coffee grounds instead of new polymers: The coffee coaster consists of a bio PE with a percentage of 25 percent coffee grounds.

What is so special about processing this biopolymer? Is there anything in particular that has to be observed?

Wouter Geldhof explains:

“The greatest challenge, of course, lies in the coffee component, that is, in making sure the material stays dry and does not degrade. The material varies in viscosity, which is not easy to manage, and so the injection molding process and the injection molding pressure have to be brought under control. All of that while maintaining low-temperature margins.”

How was KraussMaffei able to support you? Are you happy with the results?

Wouter Geldhof answers:

“The KraussMaffei team provided us with excellent support in the design process and project engineering. The same is true for their service. Together we found an optimal solution.

“Since the beginning of this year, the CX 130-750 has been producing the coasters in a four-cavity mould with a clamping force of 1300 kN and cycle times of 30 seconds. By the end of the project, we have produced about 200,000 pieces. The global demand exists. We are very satisfied with the hydraulic injection moulding machine CX 130-750 from KraussMaffei. With its cantilevered, compact clamping unit, the powerful injection unit and the compact installation area, it is ideal for our requirements of maximum efficiency in the smallest floor space.”

The intelligent energy management has further advantages, which we are benefiting from now in particular in these times of rising energy prices. Overall, we have three CX 130-750 injection moulding machines of a nearly identical design from KraussMaffei.

The CX series is evidently perfect for producing these coffee coasters. What other industries do you serve with this machine?

Wouter Geldhof proudly presents:

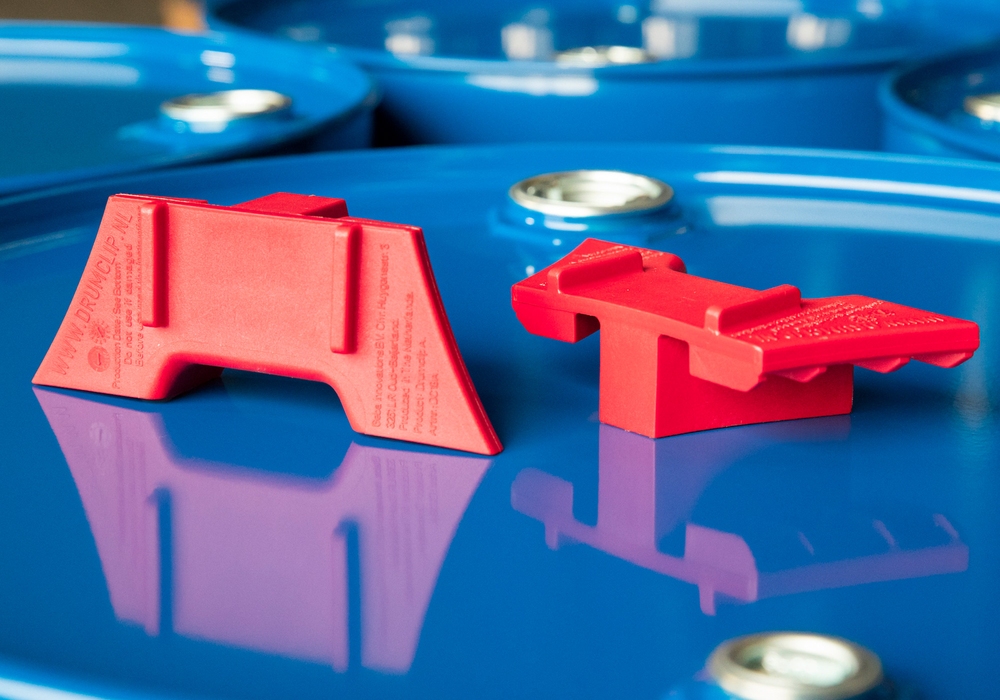

“One of our flagships, we are very proud of, are the so-called Drumclips. They are also produced on a CX 130-750. These can be used to secure (oil, chemical, additive) drums on pallets and trailers. The system is certified and gives our customers a maximum degree of security and safety.”

Do you use digital solutions? What advantage do they bring to your daily business?

Wouter Geldhof says:

“For the production of the Drumclips, we use the APCplus machine function. It is ideal and reliably supports us in the production of these safety-related and certified components by means of consistently high component quality and comprehensive documentation. I can always recommend APCplus.”

“We have also tested the social production app from KraussMaffei. Particularly for us as a smaller company, where there cannot always be someone on-site at the machine, these kinds of digital service and maintenance programs are of particular interest.”

What are your plans for the future? Are there any further innovative products in your pipeline?

Wouter Geldhof:

“There is a big demand for our Drumclips. Thus, we are considering expanding our production. That could also include an expansion of the clamping force to 2500 or 3000 kN, that is, a CX 250 or CX 300 or even a PX machine.”

“Currently, we are working on another very interesting project, a sustainable follow-up project to the coasters. This time it concerns coffee cups also made on the basis of ground coffee beans. Then we would have another stylish and sustainable part of the accessories collection and thus another perfect example of our solutions developed “outside the box.”

The future of sustainable plastics: Headland Technology brings eco-friendly KraussMaffei injection moulding to Australia and New Zealand

Headland Technology is the exclusive Australia and New Zealand sales and service provider for KraussMaffei injection moulding machines. With our extensive expertise in plastic processing equipment, Headland helps customers select the right KraussMaffei machine for their needs and provides ongoing maintenance and support. As leaders in the industry, Headland Technology and KraussMaffei are committed to advancing sustainability in plastics manufacturing. KraussMaffei offers a range of energy-efficient machine models to reduce environmental impact. We also provide guidance to customers on eco-friendly materials, recyclable product designs, and responsible manufacturing practices. With an eye toward the future, Headland and KraussMaffei aim to equip the next generation of plastics manufacturers with innovative, eco-conscious solutions for injection moulding production. By partnering with customers to implement sustainable best practices, Headland Technology enables the plastics industry to thrive while protecting the planet.

Are you a plastics company looking for the perfect injection moulding machine?

Call the experts at Headland Technology! With years of experience in the plastics industry, our knowledgeable staff can help find the right injection moulding equipment to fit your production needs and budget. Don’t compromise on quality – get the machine you need from a supplier you can trust.